Our Capabilities

Assembly

Metalcraft Technologies Assembly and Structures team produces small to large aerostructures and assembled components for multiple commercial, military and general aviation aircraft. The majority of our assembly work scope includes:

- Beams

- Panels

- Rails

- Intercoastals

- Fairings

- Enclosure

- Sections of Wings and Fuselages

Our highly skilled and trained workforce has experience on numerous platforms and in-depth knowledge of major OEM’s specification and processes. We’re certified and approved to perform all of the following assembly functions for all of our customers:

- Multiple Bonding

- Resistant Testing

- Fastener Installation

- Bushing and Bearing Installation

- Sealing Applications

This versatility allows us to deliver high quality assemblies on-time to our broad customer base.

HOW WE WORK

Our System of Integrated Processes

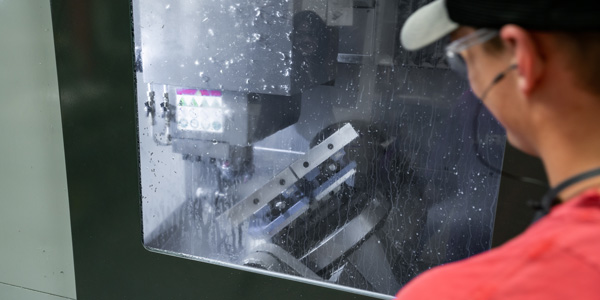

Drawing on years of aerospace fabrication and machining talent, our teams are equipped to create unique aerospace solutions for our customers.

DESIGN

DEVELOP

DELIVER

IMPROVE

Capabilities & Service

Metalcraft’s multiple capabilities are vertically integrated. Our one-stop shop aerospace manufacturing solutions allow our customers to see their designs produced from start to finish under one company umbrella. Allowing for high quality, streamlined communication, and shorter lead times.