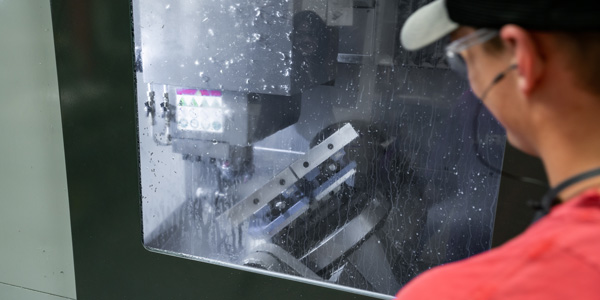

Our Capabilities

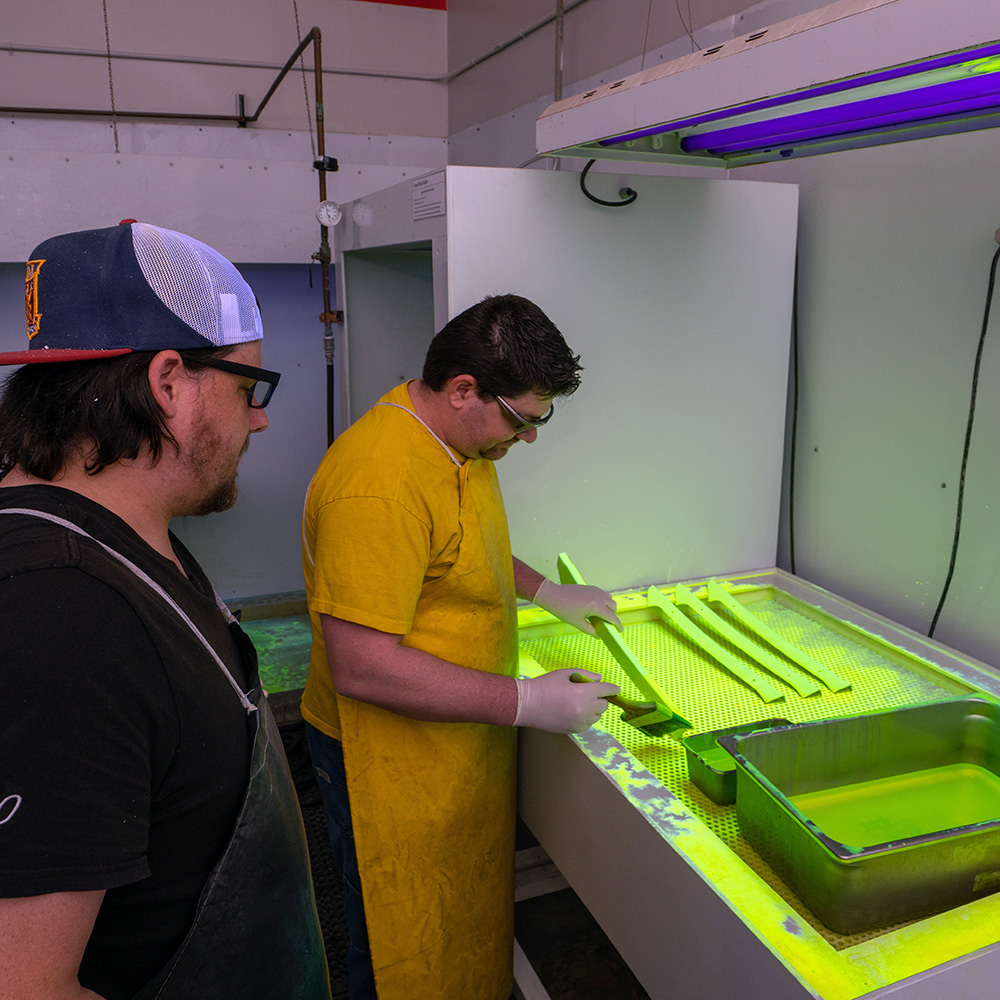

Special Processing

Metalcraft Technologies' capability to provide in-house finishing significantly reduces lead times. Special Processing capabilities include:

- Chemical Conversion Coating

- Anodize

- Penetrant Inspection

- Passivation

- Titanium Etch

- Painting

- & More

We have an automated plating line, as well as hand dip lines for parts where the configuration may present challenges for solution entrapment.

Our NADCAP certified processes provide the highest quality to ensure compliance with all specifications and regulations. Our in-house laboratory and salt spray capability ensure that we keep all of our processes in tight control. Our waste water treatment system cleans the water used to ensure we are a sustainable part of the community.

HOW WE WORK

Our System of Integrated Processes

Drawing on years of aerospace fabrication and machining talent, our teams are equipped to create unique aerospace solutions for our customers.

DESIGN

DEVELOP

DELIVER

IMPROVE

Capabilities & Service

Metalcraft’s multiple capabilities are vertically integrated. Our one-stop shop aerospace manufacturing solutions allow our customers to see their designs produced from start to finish under one company umbrella. Allowing for high quality, streamlined communication, and shorter lead times.